Status: Made to Order

Integrated Skids

Material: N/A

Power: N/A

Brand: Adam Fabriwerk

Our integrated skids are a fully integrated end to end solutions,

seamlessly integrating to cater to your aseptic process fluid handling

applications. They are ideal for handling medium to high capacities.

They can be customized and optimized to suit your requirements. The

systems design ensures 100% cleanability.

DESIGN, ENGINEERING, AUTOMATION

The systems are designed and engineered at our design centre with

experienced and highly qualified design team. The systems are built in

the latest simulation and CAD soware and visualized in 3D before being

approved for manufacturing. All the equipments are fully integrated to

perform as a single system with high quality and reliable automation.

They are programmed in accordance with S88 and automated in

accordance with GAMP 5 standards and are 21 CFR part 11 compliant.

TESTING & FACTORY ACCEPTANCE TEST (FAT)

All systems are tested at our dedicated FAT testing area that are fully

equipped with all required utilities. High quality testing instruments

ensure the systems work fine under the designed conditions. Our QA

team ensures complete documentation that are required before and

during the FAT.

KEY FEATURES

- Designed as per US FDA / cGMP / ASME/ PED/ compliance with

ASME - BPE norms

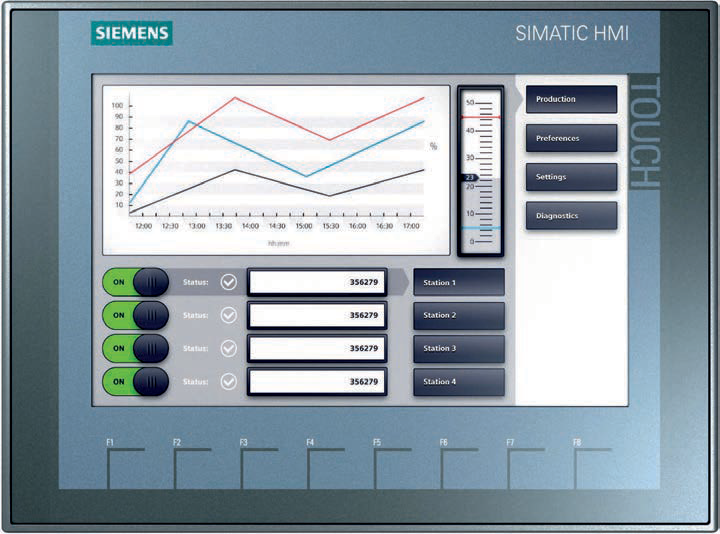

- 21 CFR part 11 compliant, fully automated PLC controlled touch

screen HMI

- Bottom mounted magnetic mixers with options for low / medium /

high shear applications

Flush bottom outlet valve with sampling / sterilization

configurations

- Sterile flange connections of top dish / side ports to enhance CIP /

SIP operations

- pH, temperature, conductivity, DO sensing through sanitary port on

vessel shell

- Load cell for weight measurement / Level sensors for level

measurements

- Block valves for dead leg compliance and compactness

- Components and instruments from reputed international vendors

- Interconnected product piping through sampling systems and

pumps with filtration skids

CAPACITY

5 - 30,000 Litres.

Powered by Froala Editor